Filter presses and thickeners EMO

|

With experience of 20 years and more than 2500 objects established in 65 countries around the world, EMO - the leading designer and the manufacturer of processing equipment of processing of a deposit, for a condensation, dehydration and drying. Among manufacturers of tape filter presses and tape thickeners, EMO always I was the leader of the market of development convenient in use and optimum on a ratio the requirement efficiency of the equipment. |

|

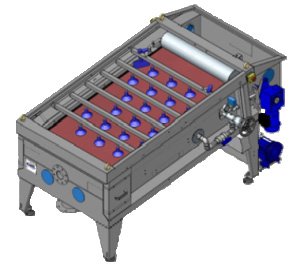

Gravity belt thickeners of a sludge of OMEGA are intended for continuous mechanical dehydration of a sludge of domestic and industrial sewage.

This simple and effective technology is directed to reduction of weight of a sludge not less than by 4 times with the following characteristics:

- low consumption of energy,

- a design from stainless steel,

- low and easy operational costs and control. |

|

|

The gravity belt thickener of a sludge OMEGA SD with a capañity of 1-35 m3/hour is used as:

-

the final stage to reduce humidity of a sludge to 92-94%, thereby replacing a usual gravity static thickener;

-

a stage of preliminary dehydration in combination with a balte filter press for optimization of work and productivity of the last;

-

a stage of preliminary dehydration to a plate filter press or the centrifuge to reduce the size of the equipment of dehydration;

-

for reduction of volume of sludge before process of an anaerobic digesrion process to reduce the digester size.

The gravity belt thickener of a sludge OMEGA MD with a capañity of 1-70 m3/hour is used as:

-

the final stage to reduce humidity of a sludge to 92-94%, thereby replacing a usual gravity static thickener;

-

a stage of preliminary dehydration in combination with a balte filter press for optimization of work and productivity of the last;

-

a stage of preliminary dehydration to a plate filter press or the centrifuge to reduce the size of the equipment of dehydration;

-

for reduction of volume of sludge before process of an anaerobic digesrion process to reduce the digester size.

The gravity belt thickener of a sludge OMEGA LD with a capañity of 1-90 m3/hour is used as:

-

the final stage to reduce humidity of a sludge to 92-94%, thereby replacing a usual gravity static thickener;

-

a stage of preliminary dehydration in combination with a balte filter press for optimization of work and productivity of the last;

-

a stage of preliminary dehydration to a plate filter press or the centrifuge to reduce the size of the equipment of dehydration;

-

for reduction of volume of sludge before process of an anaerobic digesrion process to reduce the digester size.

OMEGA THC is specially designed for constructions of very high capacity instalation. Components are adapted to working conditions up to 200 m3/hour of the raw sludge.

The gravitational belt thickener of a sludge OMEGA THC is used as:

-

the final stage to reduce humidity of a deposit to 92-94%. thereby replacing a usual gravitational static thickener;

-

a stage of preliminary dehydration in combination with a tape filter press for optimization of work and productivity of the last;

-

a stage of preliminary dehydration to a chamber filter press or the centrifuge to reduce the size of the equipment of dehydration;

-

for reduction of volume of slime before process of an anaerobic peregnivaniye to reduce the autoclave size.

|

|

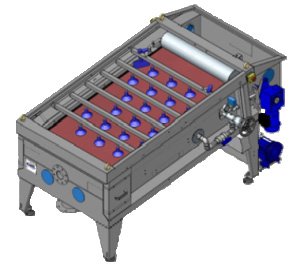

Belt filter presses OMEGA it is intended for continuous mechanical dehydration sludge of domestic and industrial sewage. EMO offers the wide range of belt filter presses which approach any output, considering the following main features:

- high-quality components (only from stainless steel);

- low consumption of energy and operational costs;

- the isolated process;

- devices of protection of operators;

- an easy access for supervision and service;

- visual control of sludge in the course of dehydration. |

|

|

The most compact in a line of production of EMO the belt filter press of OMEGA SC with a productivity up to 6 m3/hour has completely closed design in a basic configuration

OMEGA SC is suitable for treatment facilities and has the following advantages:

-

high quality of components (a design only from stainless steel),

-

low operational costs and energy consumption,

-

the closed case,

-

protection of the operator,

-

easy access for supervision and service,

-

visual control of sludge in operating time,

-

easy access to all components.

The belt filter press of OMEGA 100000 with a productivity up to 12 m3/hour is suitable for treatment facilities and has the following advantages:

-

high quality of components (a design only from stainless steel),

-

low operational costs and energy consumption,

-

the closed case,

-

protection of the operator,

-

easy access for supervision and service,

-

visual control of sludge in operating time,

-

easy access to all components.

The belt filter press of OMEGA 1000 with a productivity up to 30 m3/hour is suitable for treatment facilities and has the following advantages:

-

high quality of components (a design only from stainless steel),

-

low operational costs and energy consumption,

-

the closed case,

-

protection of the operator,

-

easy access for supervision and service,

-

visual control of sludge in operating time,

-

easy access to all components.

|

|

|

Plate filter press are designed for dehydration of industrial and municipal sludges.

Sludge compresses with a pressure of 15 bars between filter fabric. Sludge can "is condensed" in several ways, including addition of polymer, lime or chloride of iron. duration of process depends on type of the pressed slime.

The EMO produce plate filter press of three types:

-

FPM with a productivity of 35-1300 liters with manual system of shift of plates,

-

FPAC with a productivity of 190-7890 liters with semi-automatic system of shift of plates,

-

a filter press with system of automatic work.

|