Flotation units

|

KEMEO - the large player and the reliable partner in production of floatation units and other equipment which has a wide experience in the field of wastewater treatment. Experience of KEMEO covers decisions for city wastewater treatment plants, plants and factories. |

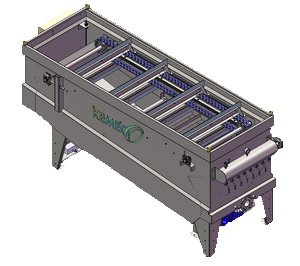

| The Alpha dissolved air flotation systems |

|

|

The Alpha flotation units are designed to treat wastewater with high solids loading. The capacity of the Alpha unit ranges from 5 m3/h up to 200m3/h. The Alpha series are designed to create the optimal circumstances for easy separation of the solids. The large free surface area and long retention time guarantee an optimal separation performance. The solids are collected in the sludge thickener and transported to the sludge cone with a low friction scraper system. The sludge can be discharged with the sludge pump for thickening or discharge. The Alpha+ flotation unit is equipped with a sludge conveyor for discharge of heavy solids. The advantages of the Alpha DAF unit:

|

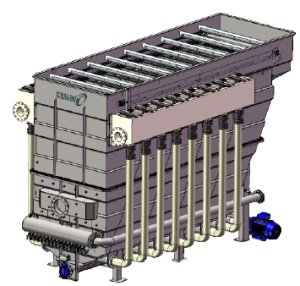

| The Delta dissolved air flotation systems |

|

|

The Delta flotation units are designed to treat wastewater with medium solids loading. The capacity of the Delta unit ranges from 5 to 200 m3/hr. The Delta series are designed to treat the wastewater using the Kemeo Platepack System. The Kemeo Platepack System multiplies the separation surface for effective separation, making it possible to treat a large amount of wastewater on a small footprint. The solids are collected in the sludge thickener and transported to the sludge cone with a low friction scraper system. The sludge can be discharged with the sludge pump for thickening or discharge. The Delta+ flotation unit is equipped with a sludge conveyor for discharge of heavy solids. The advantages of the Delta DAF unit:

|

| The Gamma dissolved air flotation systems |

|

|

The Gamma flotation units are designed to treat waste water with medium solids loading. The capacity of the Gamma units range from 225 to 600 m3/hr. The advantages of the Gamma DAF unit

|

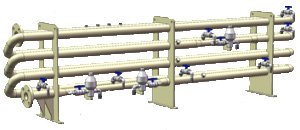

| Flocculators |

|

|

In the flocculator, chemicals are added to the waste water to coagulate the pollution in the wastewater into flocs, which are fit for separation in the flotation unit. A properly designed chemical treatment step is essential for the proper functioning wastewater treatment system. In most cases a flocculant, a coagulant and a neutraliser are added to the wastewater to create flocks, which are fit for separation in the separator. The neutraliser can be necessary to increase the pH to prevent acid environment in the separator. The type of chemicals and the dosing rates are an imported factor in the engineering of the wastewater treatment system and can be obtained by a JAR test. The flow through the flocculator is monitored to optimise the chemical dosing, to have good process control and to prevent overdosing. Unlike conventional tank flocculators, this flocculator is of the plug flow reactor type. The required mixing capacity is obtained by energy exchange due to turbulence The advantages of the KEMEO flocculators:

|